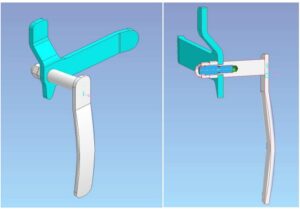

We are also considering such a device with more than 1000 parts.

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

Thank you for your hard work this week.

I update this blog once a week.

The blog was a little late last week.

I would like to do my best this week.

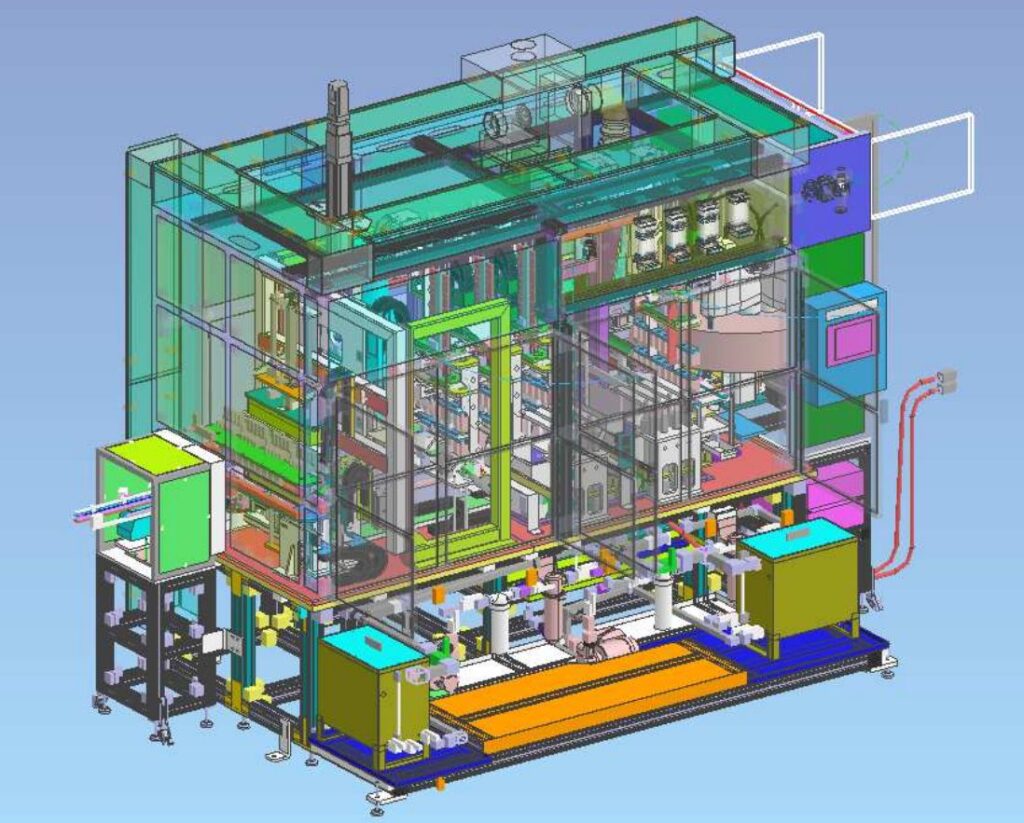

Recently, I’ve been working hard to promote the equipment design work of “NK-Design”, the main office of Industry Lab, and I would like to blog about the content that was highly evaluated when I tweeted about it.

Recent facility design work

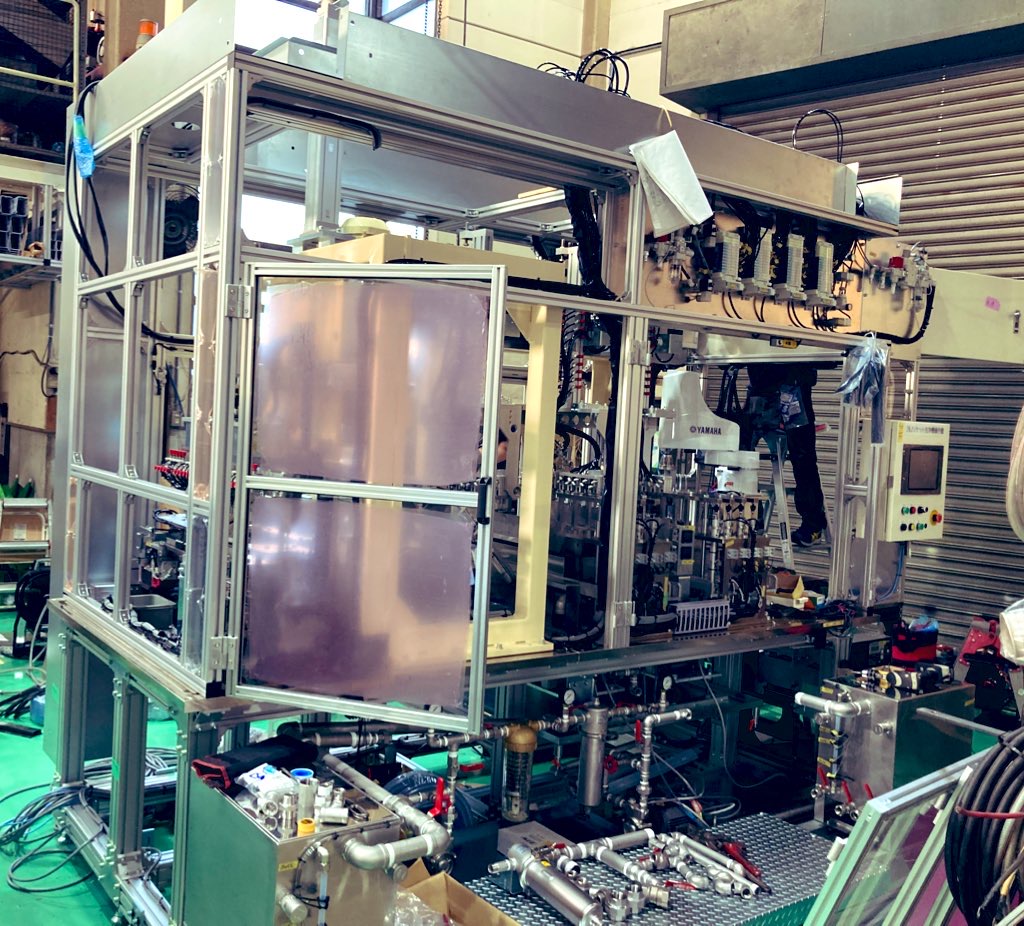

This photo is a photo of the equipment being assembled based on the drawings created by NK-Design.

Let me be firm,

We ask our customers to understand that it is okay if the workpieces (products handled by the equipment) are not shown in the photos.

What does this equipment do?

The work (product) that has just been made is fully automatically pulled into this facility,

Clean by soaking in cleaning liquid such as chips and oil,

Blow it dry and send it to the next step.

This is a device that does everything automatically.

It sounds easy in words, but

The work (product) must be cleaned from corner to corner, so various movements are performed by hand.

In addition, there is a rule called “cycle time” that says, “Wash once every few seconds.”

That’s why there are 16 units inside.

In addition, for safety, a cover that prevents human hands from entering while the device is in motion,

Just like electrical appliances have outlets, there are also cords in the moving machines that are placed in each part.

It is quite a difficult device to connect a plumbing duct through which the cord passes and a device that keeps the cleaning liquid clean.

These facilities are

First of all, purchased parts (for example, motors) and

It is divided into production parts that connect parts to be purchased.

Designers draw their own part drawings for the parts to be manufactured.

There is a process of actually buying and making a list of purchased parts and production parts.

This device has more than 1000 parts including all purchased parts and manufactured parts.

So the designer thinks about more than 1000 parts,

I’m trying to put them together and make them work.

What Industry Love can do

This itself is an advertisement of what I can do as a business office,

I’m really thinking about parts and moving things all the time,

Knowledge and experience keep coming.

I started Industry Lab with the idea that I could use this knowledge and experience to respond to the problems of general customers and customers in other industries.

The moment I thought I wanted to make something like this,

Also, even if you can’t imagine the shape, I think that there is someone who wants something with such a function here.

If ready-made products are sufficient, we recommend that you purchase them.

However, when there is no ready-made product, I think Industry Lab may be able to help.

My favorite tool is physically broken and out of print.

You can’t find good off-the-shelf products

I think Industry Love can be of help in times like these.

For those of you who have been told that you can’t make a product without a drawing at a processing shop, our company is also a drawing expert, so we can create a drawing.

We can provide drawings, and we can also provide parts manufactured based on drawings.

Please contact us if you have any problems.

I believe there is something I can do for you.

Whether it’s a facility design job or a problem with parts, I’ll do whatever I can at my office.

Thank you for reading today.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao