Hood handle production Part 1 [reverse engineering]

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

Thank you for your hard work this week.

The temperature has gone down a lot, isn’t it?

Thank you for your health care.

Well, this week is about making a hood handle.

This is an inquiry I received from the Internet.

I would like to write how it went this time.

Honor handle production request for symmetrical shape

I haven’t heard the details, but it seems to be the handle of the hood opening and closing part of an old truck or something.

I think one side of this is damaged. It was a story that I want you to make a symmetrical part by looking at the part on the other side.

Metal sheet metal is a relatively strong field.

(“Sheet metal parts” are parts made by bending steel plates of standard thickness)

Thank you for accepting.

By the way, even with sheet metal, if it is curved in three dimensions, it will become a very difficult property.

In the discussion, there is a similar part that has a female thread instead of a male thread.

Looking at the picture, I decided that this is also possible,

I decided to proceed with remodeling by adding a screw to the female screw handle.

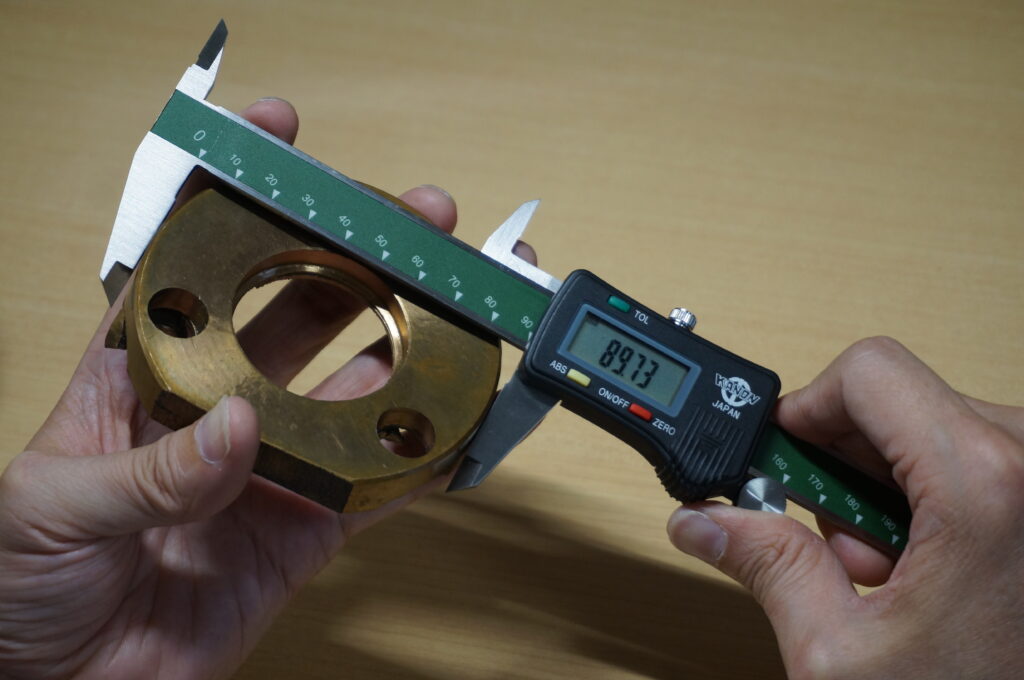

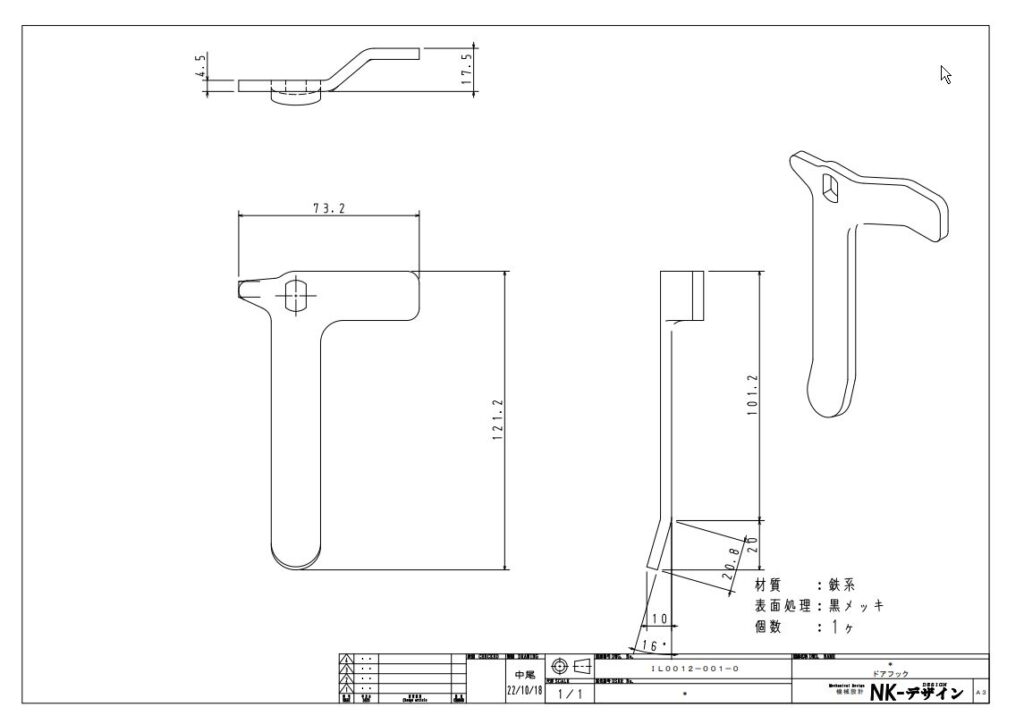

Measured from arrival of parts

Well, the story was decided and the parts were sent.

Industry Lab is located in Aichi Prefecture, and we received an offer from a person in Kyushu, and parts arrived from afar.

I am grateful for this alone.

From here on, I’ll show off my skills,

Measure the part and draw the shape.

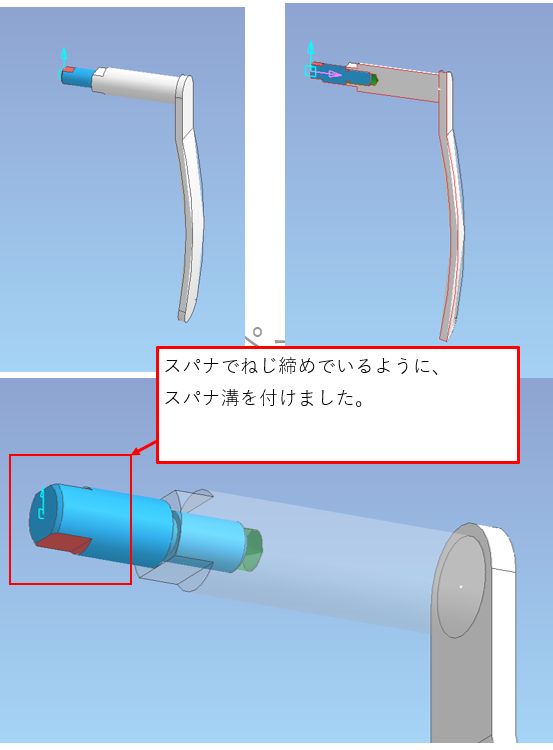

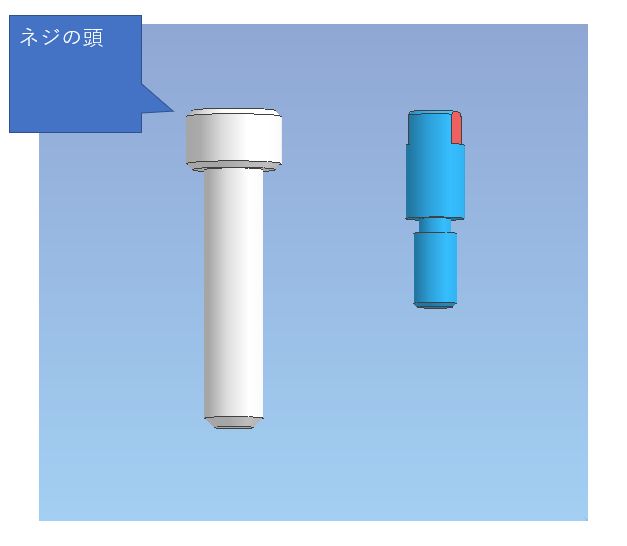

Suggestions for width across flat

And here is a proposal from Industry Love.

First of all, about remodeling the female screw handle.

I would like to consult with you if you want to add a stepped shape to the tip of the screw like this.

Technically, this is called “double width”.

The reason why I use this is to hook a spanner or pinch it with pliers,

Used for tightening screws.

Without this, it will be difficult to tighten all the way through, and if you pinch the threaded part with a tool, the threads will be crushed.

A question from a customer

“Will the nut attach properly with the width across flats?”

From the conclusion, “it will be attached properly”.

I was stoked when I heard this.

I took it for granted at the machine shop, but there were many things that non-experts didn’t know, and I regretted that I wasn’t able to provide detailed explanations.

I will continue to explain as carefully as possible, but if there is anything you do not understand, please feel free to ask me.

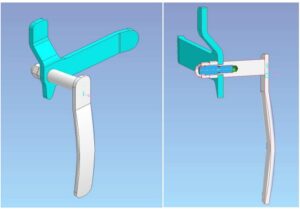

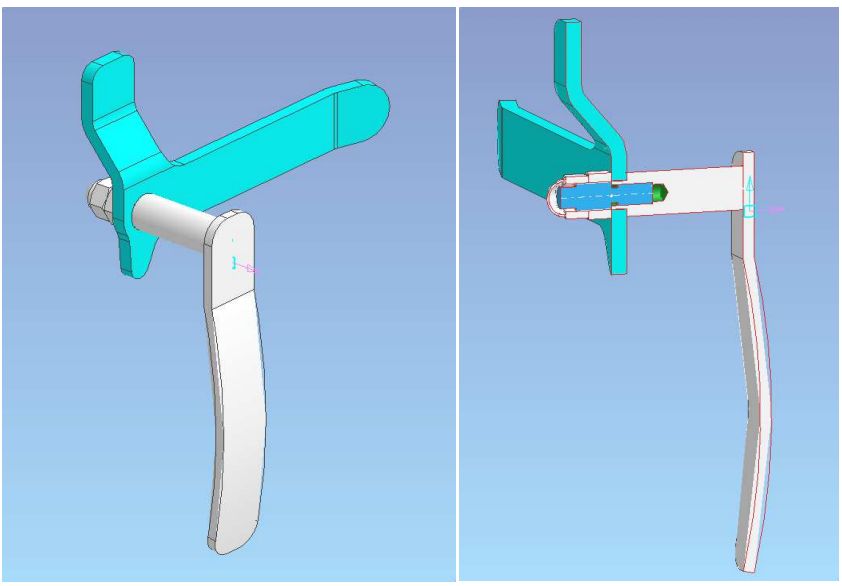

Submission of 3D images

The story went a little sideways,

Regarding the width across flats, we received an OK, so we created a 3D data image and showed it to the customer.

Those who are in the field of machines look at the drawings,

It is quite difficult for the general public to see the drawings, so Industry Lab tries to give these 3D images to our customers.

After seeing this, the customer was satisfied.

Then, we will give you an estimate and start the actual production.

I have a lot of things I want to write, so I will write the actual production in the second half,

I’m thinking of writing a separate production example blog.

Difficulty of reverse engineering

Reverse engineering is the process of reading the shape of an existing part and using it for reproduction or the next design.

There are many more complicated parts in the machine shop, and this handle part looks simple at a glance once you get used to it, but there are various problems before handing it over to the production side.

This time, I was worried about the hook-shaped oval hole.

The hole of the old part has been deformed due to use, so I can’t read the shape obediently,

We will decide by looking at the balance with the other parts.

I don’t want it to be too wobbly, so I’m aiming for a size of about 0.1mm.

The rest is the length of the handle modification screw.

This time, there is almost no head part like a normal screw, so I decided to attach the thin screw to the bottom of the tapped hole.

I had a hard time aiming for it.

And there are many things to think about even with a small amount of parts.

I don’t think you’ll be able to do it right away unless you gain some experience in this area.

What I am good at is drawing

So this time the customer is from Kyushu.

I heard that they asked a processing shop in Kyushu if they could make a few items, but the answer was that they couldn’t make it without a blueprint.

I heard Industry Lab was a last resort. smile

I certainly don’t understand why you want to refuse.

Why?

Because it is absolutely impossible to make the exact same thing as the old part.

Even if you make it in the same way, some deviation will definitely come out.

In that case, even if it is not usable, we cannot guarantee it. I really think so. That’s why I don’t want to make I understand.

But it’s the same with mass-produced products.

Strictly speaking, no two parts are exactly alike.

Then what should we do?

Thinking about the function and what part is really necessary, I put conditions such as “If you can make it within this range and within this range, there will be no problem.” That’s the drawing.

The drawing not only indicates the shape, but also indicates the allowable range.

That’s why designers have a big responsibility.

But the responsibility is on the designer, so the parts can be made.

I summarized it in a cool way,

What Industry Lab is best at is making drawings.

In fact, I’m always nervous because I’m afraid that I’ll make a mistake as a result of taking responsibility.

By the way, the price you are interested in

It was about 40,000 yen for screw parts, hook parts and drawing fees.

If you have any questions for Industry Lab,

Please for your reference.

Well, I’m glad if you look forward to the second half of the blog.

Thank you for reading today.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao