Perfect installation of the air conditioner (Part 2: Making parts)

Thank you for your hard work this week.

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

It looks like the rainy season is over.

The temperature is rising and so is the humidity.

It has become hot. Please be careful of heat stroke.

【cloud】

“Finally the rainy season is over”

Humidity can make you feel uncomfortable.

I got the air conditioner working.

I think it’s good that the air conditioner was installed early.

By the way, last time

I made a table to install an air conditioner.

[Picture of table]

“Making additional parts”

Now, I thought that all I had to do was make a stand and install an air conditioner,

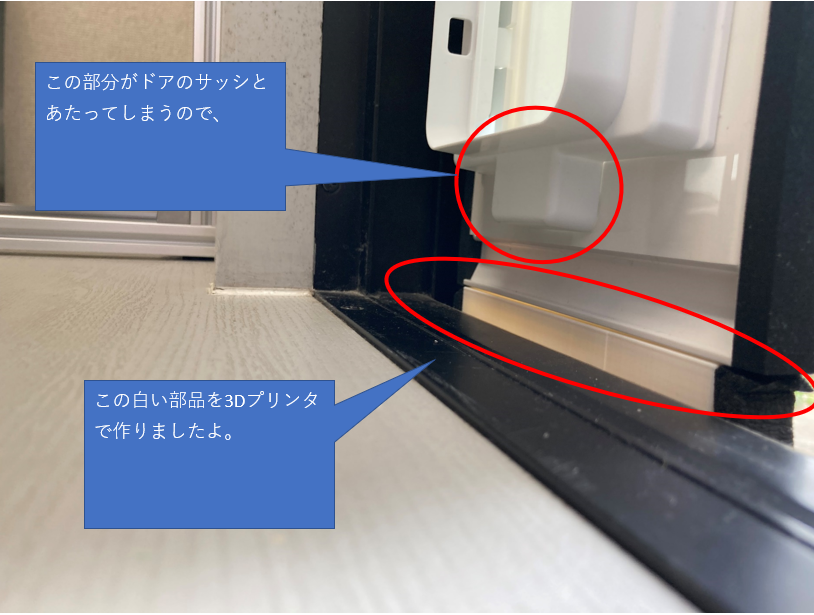

I tried to fit the panel of the window frame where the exhaust duct is attached,

It doesn’t go well because the sash hits the panel.

Then, this is the turn of Industry Love, which provides the perfect fit, so we will manufacture the parts.

[Description photo]

“Things to think about when making parts”

The first thing a designer thinks about when making a part is how to make it.

Is it machined, sheet metal, or 3D printed?

If you want to make parts with Industry Lab, it is easiest to use a 3D printer that can be made in the office, so this time I will use a 3D printer.

Of course, it is the result of judging that it will be okay considering durability etc.

“3D model making”

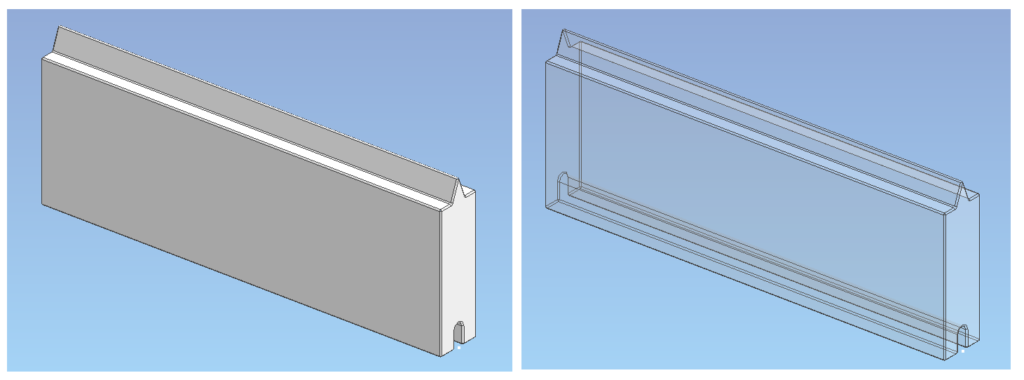

Once decided, it is time to create a model for printing.

To make a model, we first measure the necessary parts.

I will take measurements.

It is important to make parts accurately, so measuring is a very important task.

If you can measure it, make a model.

【model】

The model is completed like this.

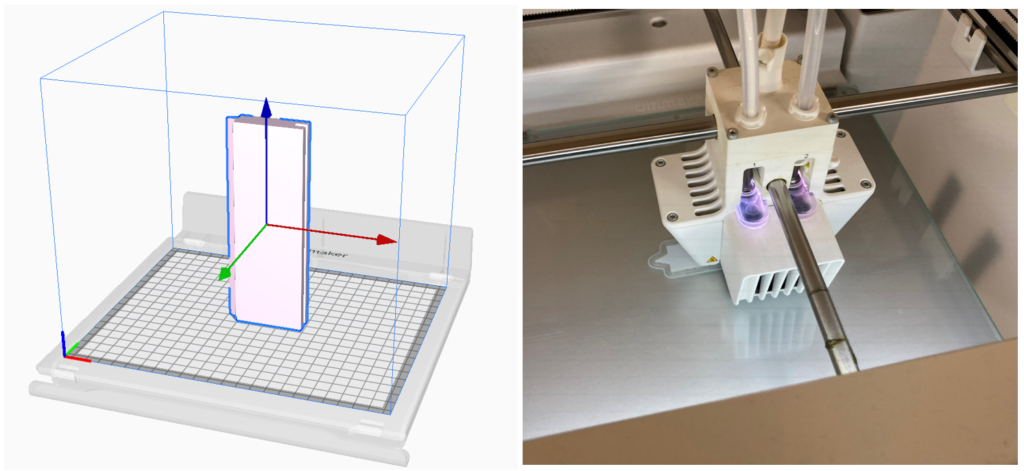

“Model, then slice”

Once the model is complete, the next step is slicing.

Slicing is the work of thinking about how to print layer by layer when printing with slice software.

There are various settings for slices, so some experience is required.

【slice】

After slicing, just start printing according to the slice.

“In reference”

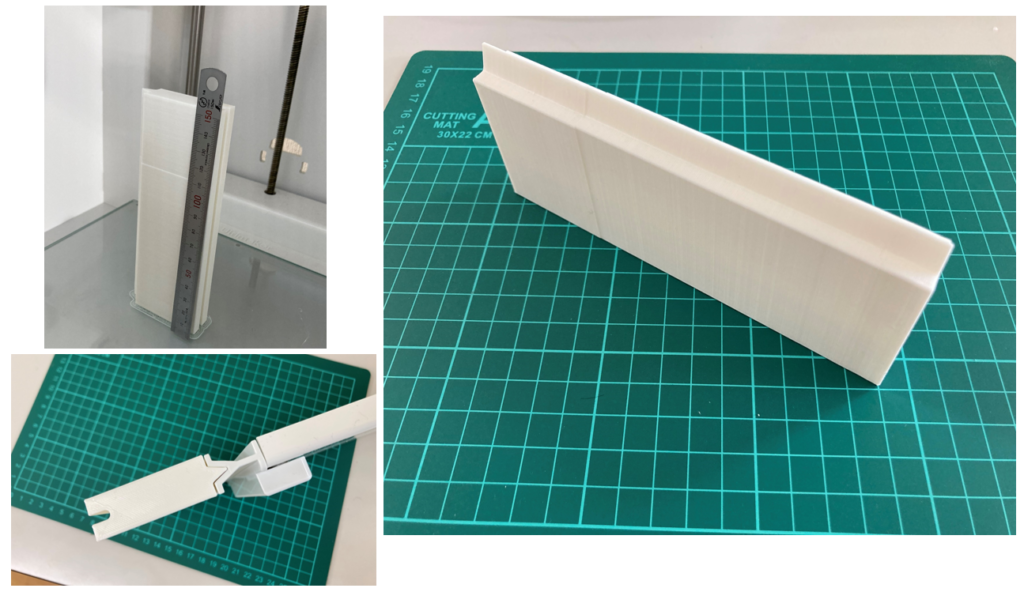

I just ran out of materials, so I’ll show you the parts in the middle of printing.

As you can see, the inside is hollow, but it is reinforced with triangular ribs.

There is also a meaning of saving materials,

It seems that the inside is better in terms of dimensional stability.

[Inside photo]

“Print complete”

And the print is completed.

In this way, it fits perfectly with the mating part.

[Parts photo]

“Completed by inserting the panel”

If you can do this, all you have to do is assemble it.

[Inset photo]

Hmmm. It fits well.

If you design it properly, it will fit perfectly.

I hope I can make it through this summer.

Come on, let’s work hard from now on.

Thank you for reading today.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao