Machine sommelier!? + Nameplate making

Thank you for your hard work this week.

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

It was hot again this week.

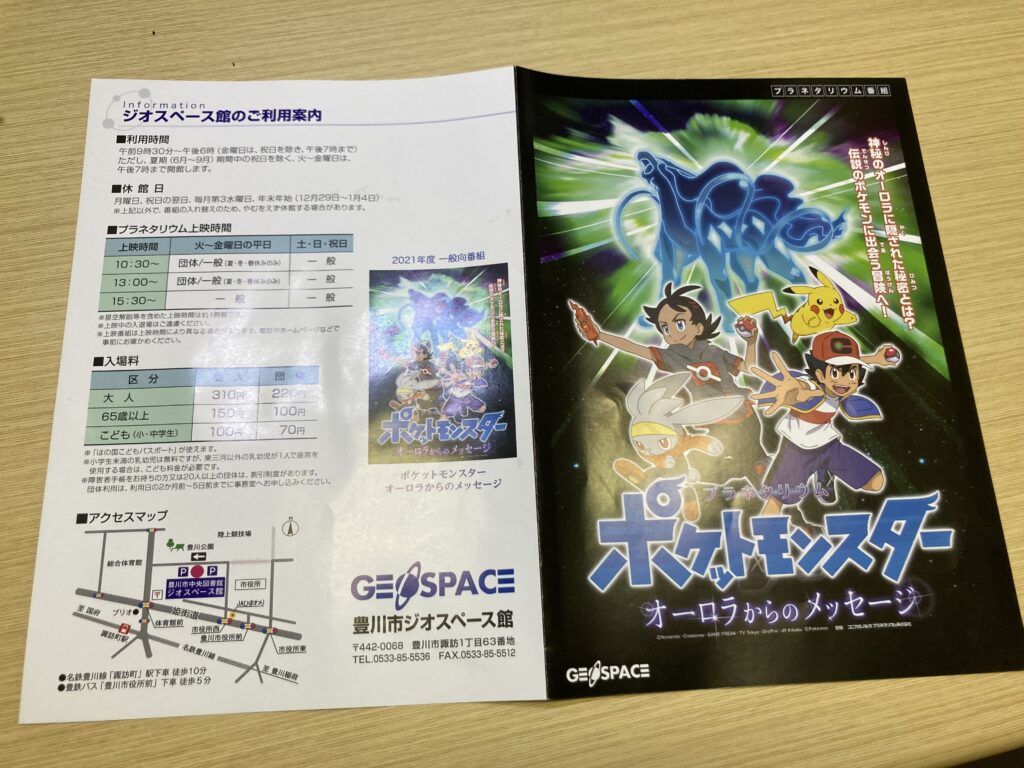

Well, this weekend, I took my child to a planetarium in Toyokawa City, Aichi Prefecture.

In Toyokawa City, there is a planetarium called Geospace Hall in the library, and almost anything is shown except when the library is closed.

Now in the morning, we are showing a program called “Message from Pokemon Aurora Pokemon”.

This is interesting for children,

It’s very good to watch with children during the summer vacation because it is a content that combines the universe and Pokemon.

It is recommended.

In addition, at the Geo Space Hall, there is a program about the universe with Chibi Maruko-chan,

We also do some shows for adults.

It’s fun because the curator’s explanation of the universe is also educational.

I’ll do the introduction around here.

This week’s Industry Love talks about content

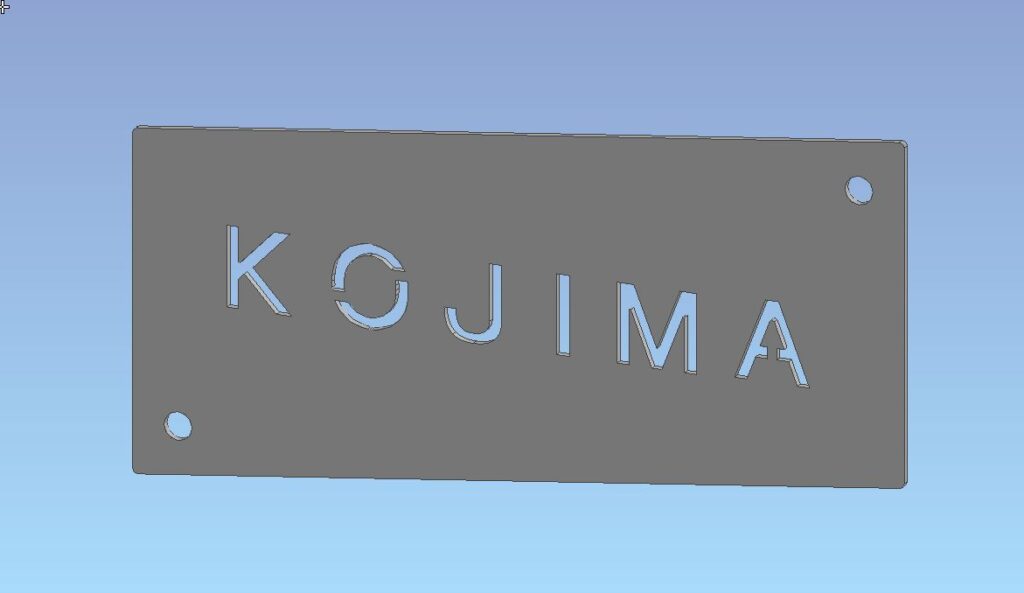

Well, industry love is making a nameplate.

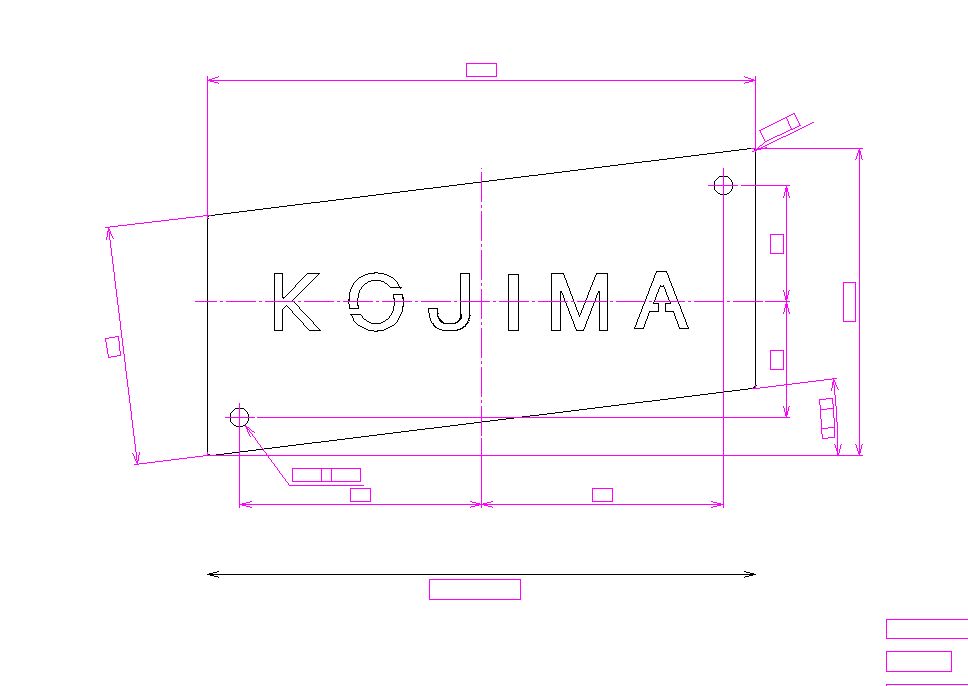

I was discussing the design of the nameplate of “Kojima-san” now, but the shape has been decided.

It’s like this.

Instead of a perfect square, I made it an oblique shape that goes up to the right.

This is a design that incorporates the idea that the Kojima family will continue to grow.

Now it’s finally time to arrange

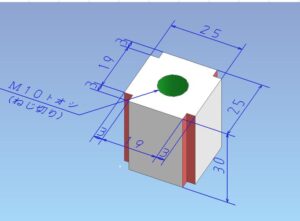

I made a drawing like this.

We are currently discussing this with the production side. 😊

I think I’ll make it a proper blog again when things are completed.

Now for another content

Industry Love, which started two years ago, has recently received an increasing number of inquiries. thank you very much.

The contents include car covers that use 3D printers,

It has become quite diverse, such as metal parts and drive system units for automobiles.

I thought that if I mastered this, I would be a “machine sommelier”,

I thought I’d try to make it possible to say, “I’m a machine sommelier.”

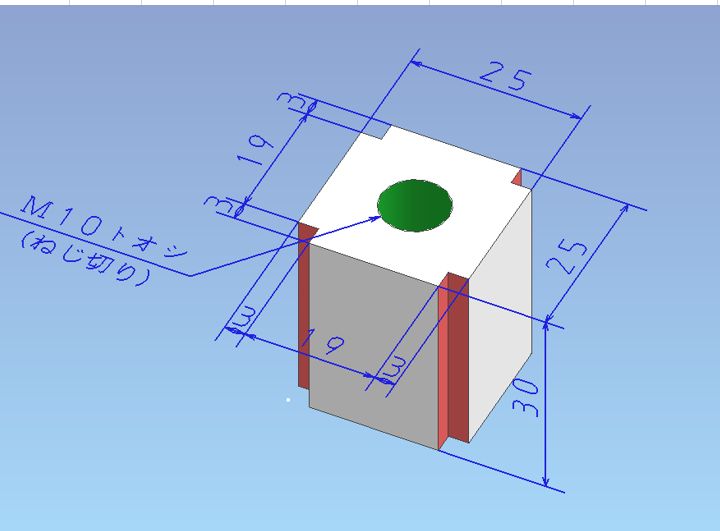

Under such circumstances, we received an inquiry asking if we could make a nut of about 20mm to 30mm.

Of course you can make it, but it’s a part that’s a little bigger than your finger.

I think that it will probably feel that even if such a small part is expensive, it will be about 1000 yen.

To be honest, as a commoner, I feel the same way.

However, what we are doing at our company is the production of one item.

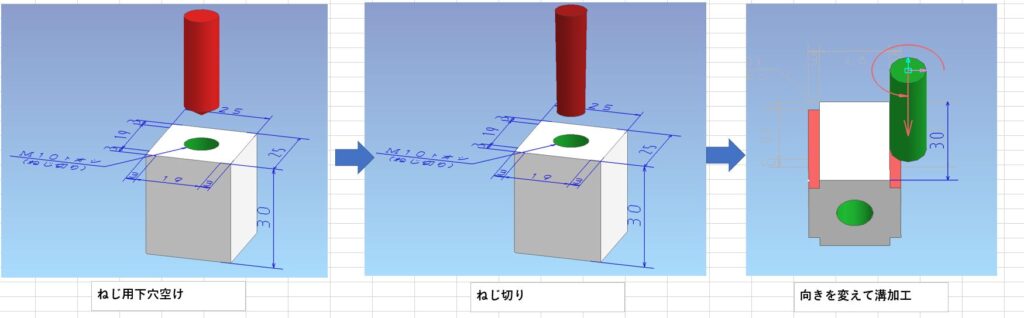

The procedure for making this is as follows.

(If made from metal)

Measure the actual damaged item and make a drawing of the part→Purchase the material→

Set it on the machine tool and make a hole → Thread cutting → Change the direction of the material and process the groove → Shape check → Surface treatment → Mail

All this will be done by humans.

Then, including the whole process, it takes about half a day no matter how short it is.

Moreover, since material costs and equipment depreciation costs are added separately,

No matter how cheap it is, you can think that it will exceed 5000 yen.

Wait a minute, do home centers sell nuts for 5,000 yen each?

Some people say.

It automates the entire production process, making one piece per second.

Instead, the premise is to produce in large quantities and sell to many people.

But please try to make a fully automatic facility to make one. It’s going to be ridiculously expensive.

Therefore, it is necessary to explain and understand these small parts well.

By the way, there are also special patterns such as the following.

There is a factory worker who touches machine tools every day,

Such a person sees things and measures them with vernier calipers,

I pick up stainless steel materials (materials that do not rust even without surface treatment) that I just throw away and make parts in about 30 minutes.

Then it looks as if it can be done in an instant.

However, it is a very limited condition, and it also includes luck that the ingredients are accidentally dropped.

In addition, the depreciation cost of the equipment and the technical fee for the factory staff who use the machine tools must be very expensive if converted into money.

I’m sorry, but our company does not meet the conditions,

Even if it is satisfied, the profit for survival is decided as follows, so it cannot be cheap.

However, please be assured that we do not intend to charge exorbitant prices.

I introduced it because it was a perfect example for a sensory explanation of money.

However, basically we are doing it with the desire to help customers who are in trouble, so at a conscientious price as much as possible,

I would like to do my best to become a “machine sommelier”.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao