5th anniversary of NK-Design ~ What is important in equipment design and the future including IL

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

Thank you for your hard work this week.

Lately, fragrant oak has a nice scent.

Late October. It’s getting cooler in the morning and evening.

It’s hot in the daytime and the temperature difference is large, so please take care of your physical condition.🙏

Well, this week I thought I’d introduce what a 3D printer is like.

On second thought,

On October 25th, NK-Design, a facility design business that is the origin of Industry Love, will celebrate its 5th anniversary.

I would like to write a little bit about that.

[What is NK-Design]

As I mentioned earlier, NK-Design is a facility design facility.

“NK” is an acronym for sole proprietorship.

By the way, the reason why I added “design” is that “SEKKEI” means “design” in English.

I used to do something like accessory design, and I was interested in the Japanese image of “design”.

Without being taken by the image of Japanese “SEKKEI”,

Like the English word “design”, it is an image that shows the general idea of imagining and thinking about shapes, and I wanted to give shape to various things in the future.

At the beginning of my independence, I was desperate to make a living with my own business, so I didn’t think about it seriously.

Why did you become independent? When I thought about it, I think that the underlying thoughts of “I want to grow.”

That said, I have a life in front of me, so at first I started as a job designing equipment with the skills I learned.

Of course, even now, the facility design is the foundation of my work.

[Product design and equipment design]

In general, “design” is divided into “product design” and “equipment design.”

“Product design” can be said to be the design of “mass-produced products”.

I have also been involved in the “product design” of automobile parts.

It is important to find ways to eliminate defects in mass-produced automobile design.

For example, if there is a structural defect in the parts of an automobile that is manufactured for 200,000 units a year, it would be extremely difficult to replace all the parts that have been released into the market, and automobiles are safe. is very important, so we must carefully design each and every part so that a defect cannot endanger human life.

When I say “careful design,” I mean that we make prototypes over and over again, and conduct various tests such as strength tests and resistance tests against wind and rain.

It is also important to eliminate concerns such as interference with peripheral parts.

I think everyone reading this feels that this is very difficult to do on your own. At the company, we spend time together with company colleagues and customers to build it up. Speaking of design, it is design, but most of it is coordination work between companies, and there is a lot of paper work.

If anything, I think I liked thinking about shapes by myself. I left “product design” and went to “equipment design”.

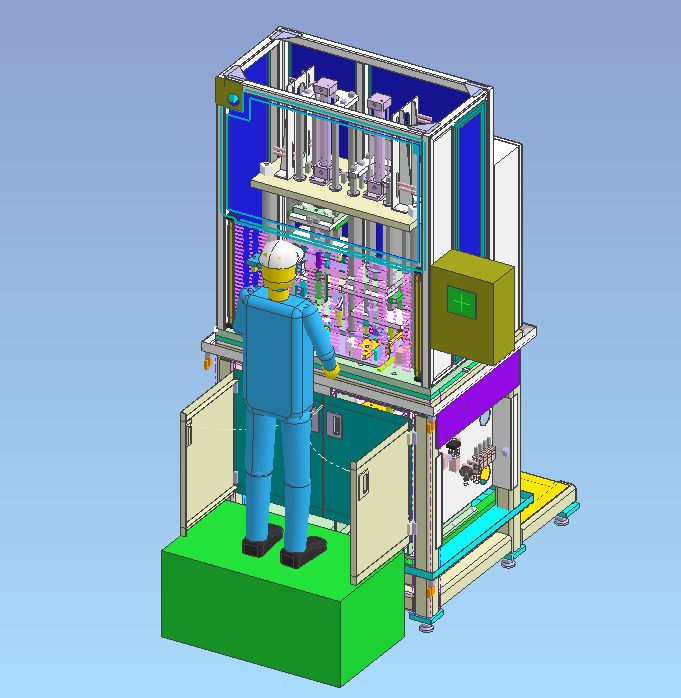

What does “facility design” mean?

In other words, it is to design the equipment (equipment) that makes the product considered in “product design”.

Although it is an image, it is like a “ordered house”, and we will create a “one-of-a-kind” device by combining products with individual functions and manufactured parts.

[Important things in facility design]

The most important thing in facility design is “speed.”

While product design takes a year or two to ensure that there are no defects, equipment design often progresses to mass production within half a year after the product shape is decided.

Therefore, there is almost no prototyping, and it is possible to move the design as it is as it is.

Moreover, although large-scale facilities are sometimes designed by a team, if anything, they are designed by individuals and the shape is decided at the designer’s discretion.

Therefore, the designer’s skill is greatly involved in the design, so the responsibility is also great, but I think it is also very rewarding.

[What I value as a facility designer]

By the way, as a facility designer, I personally think that

The question is how simple a device can be made.

When it comes to device design, we tend to think that clattering movements are cool, but a device is originally designed to repeat a specific movement with a purpose.

We are conscious of reducing the movement as much as possible, reducing the number of constituent parts as much as possible, and reducing the number of complicated parts as much as possible.

For some reason, the more you move, the more you control, the more energy you have to move.

If the number of parts increases, not only the parts cost but also the management cost and assembly cost will increase. Because it will increase the burden.

That’s why it’s hard to make it complicated no matter where you think about the amount, the site, the worker, etc.

However, there are exceptions, and there are adjustment mechanisms in hard-to-reach places,

Reducing the number of parts can also cause problems such as difficulty in assembly, so it is not just a matter of reducing the number of parts no matter what.

This is where experience counts, but there are times when we intentionally divide parts in consideration of the possibility of changes during assembly and later modifications.

In other words, how to make a smooth device quickly and without problems

It is important to consider what the end user, the assembly worker, the electrician, the processing shop, and the sales person are thinking, and when I think about various things, there are many patterns that lead to simple devices.

[As Industry Love]

Well, this blog is an Industry Love blog.

I would also like to mention Industry Love.

As I said above, I wanted to try various designs, and I started Industry Love because I thought it would be a service that suits the future era of “individuals” that are close to each person.

Thinking about it now, the service that restores broken parts is

Since the service life of the machine is being extended, I can proudly recommend it as a sustainable service.

[Why Industry Love aims to be a “machine sommelier”]

Actually, there are a lot of processing shops that make parts in the world. So why do we need industry love? I think.

Machinists have specialties, such as those who are good at sheet metal, those who are good at cutting, those who are good at welding,

Also, what we do is completely different depending on where we are good at metal and where we are good at plastic.

Then, even if you want them to make parts for you, you need the ability to decide which fabricator is the best.

Machinists are also not good at thinking about equipment and making drawings.

So at Industry Love

Unravel the content of the consultation,

Think about the necessary parts and write a drawing,

Ask the best processing shop.

That’s what I do.

Three months ago, I came up with the phrase “machine sommelier.”

Isn’t this exactly the same as a sommelier who selects the best wine for the situation and taste?

We can do this by deepening our knowledge of parts in product design and equipment design,

I think that it is a service that only I can do, who can talk with customers about accessory design and think about design.

Therefore, I would like to aim for the world’s first “machine sommelier”.

In fact, October 25th marks the second anniversary of Industry Love.

Industry Love, who was a baby two years ago, is now able to toddle.

Industry Lab is a slowly but surely growing service. I will continue to increase what I can do little by little. Slowly but steadily we will move forward.

The Industry Love mark is “blue” with images such as “calm” and “technical”.

This color scheme is made by adding pink to the image of “love” and “kindness”. By the way, the diagonal “L” is divided by “I” in the middle to create a heart-like shape.

[Thanks]

Last but not least, NK-Design 5th anniversary. thank you very much. I don’t think I could have continued like this without everyone’s help.

Equipment design is a deep industry and I have been involved in practical work for nearly 10 years, but there are still many things I do not know.

If possible, I would like to continue to be involved in this industry and learn various things.

In addition, I think that the knowledge, skills, and work colleagues that I have acquired in the process will be the strength of Industry Love, and I believe that I will be able to proudly say that I am a “machine sommelier.” increase.

And I want to aim for the next stage with that power. I will do my best in this as well, so I look forward to working with you in the future.

Thank you for reading to the end today.😊

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao