Renovation (remodeling) of equipment should be Industry Love (Part 1)

Thank you for your hard work this week.

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

It’s been a long time since I blogged.

Setsubun has passed. From now on, I’m going to spring little by little.

I think it would be good if various things go in a good direction with warmth.

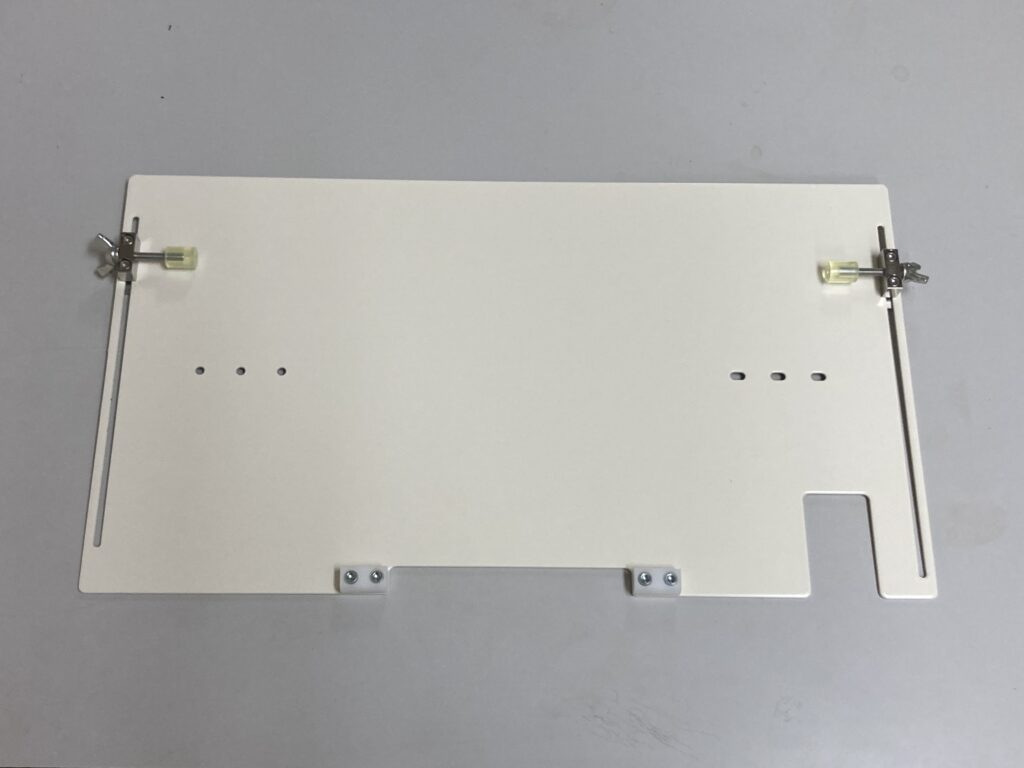

“Ordering a computer table”

By the way, I recently received an order for 10 parts.

As for the contents, it seems that the computer that operates the equipment used in a certain facility will be replaced,

It was a story to reform (modify) the table that puts on the computer.

I have also measured the dimensions of the device by disturbing the facility.

After making several prototypes, I came to the point where I thought, “This will work somehow.”

I decided to make 10 pieces with a total replacement.

“What I learned from the trial”

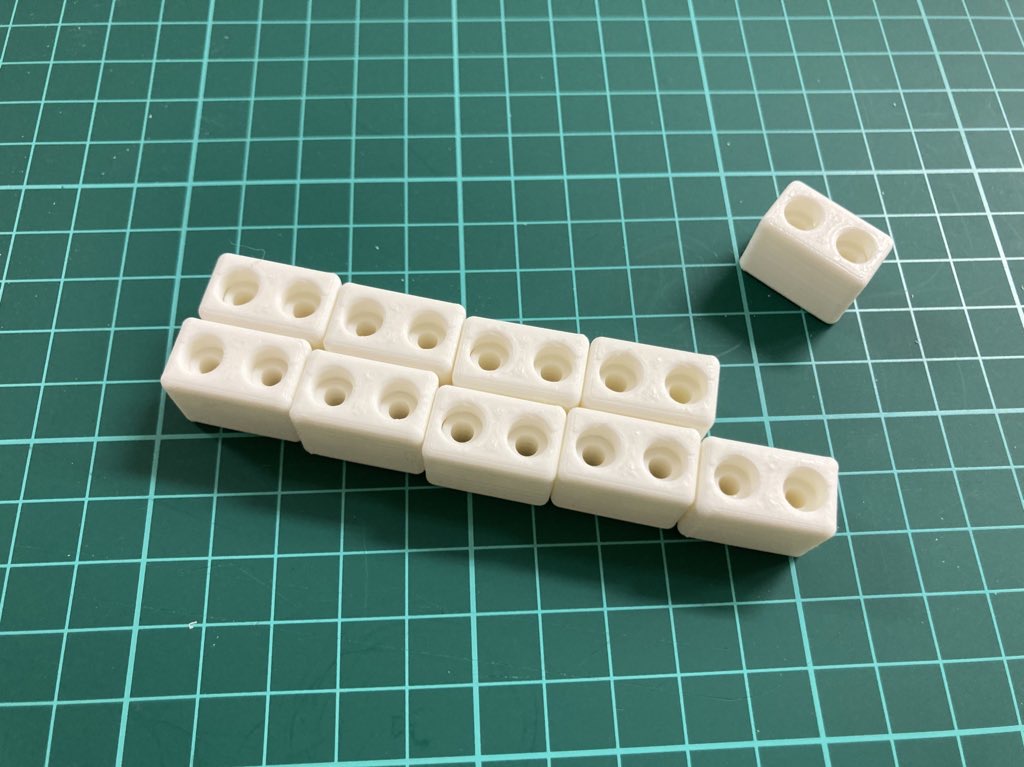

As I learned from the prototype, I don’t need to be as gentle as in the factory.

Because it is dangerous if the parts have corners,

It meant that the sharp part had to be rounded.

If you only make original parts with about 10 parts, it will be very expensive, so

CHIRIBA remodeling units are made from mass-produced products that can be selected from the catalog.

However, mass-produced products have a fixed shape, and to round the corners, additional processing must be done after purchase.

“Difficulty of additional machining”

However, if you use a machine for additional work, the price will rise again,

I don’t know what it will look like if it’s done by hand.

Also, if you post-process the metal, the precious plating will come off.

Originally, there is no choice but to use stainless steel that does not rust, but stainless steel is expensive.

“solution”

So, the solution proposed by Industry Lab was

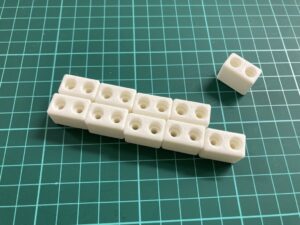

Making parts with our 3D printer.

Industry Lab’s 3D printer is a type of printer called FDM.

A resin layer of about 0.1 mm is stacked from the bottom to create a shape.

Then, streaks called lamination traces appear on the side, so it is a little difficult to see.

However, this time, the parts need function, so they don’t need to be as beautiful as a figure, so there’s no problem.

There is also strength as it is, so there is no problem if people use it manually.

“Thread cutting of 3D printer parts”

By the way, I also cut screws on parts made with a 3D printer.

I also calculated the strength, but if you use it manually, it will be fine.

“Disadvantages of 3D printed resin parts, solutions”

Basically, resin parts tend to be vulnerable to ultraviolet rays,

It is difficult for 3D printed products to have the same durability as mass-produced products.

However, if you are indoors, the effects of UV rays will be less.

Also, even if the parts are damaged, we can always supply 3D printed products made by our company.

I think there is no problem.

If you just say you’re worried,

Although it costs a little more, we can also make parts from metal, so please contact us.

[collect parts]

Parts will arrive next week.

I’m looking forward to assembling it. 😊

I’ll introduce you again when the finished product is ready.

Recently, I learned that “equipment reform (modification)”

For industry love, it’s a very good field,

I think there are very few places that can do it.

Please feel free to contact us if you have any questions.

Thank you for reading today.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao