Thoughts on the “now” of 3D printers

We are doing custom parts production in Toyokawa City, Aichi Prefecture.

Industry love.

Thank you for your hard work this week.

I’m a little behind on blogging this week.

The large-volume, short-delivery work I did about two months ago has settled down,

I suddenly got mentally tired, so I worked at a slow pace.

It’s not good if you push yourself too hard.

That said, there are many jobs that you can’t finish without overdoing it.

I hope that there will be no irreversible damage to all of you.

Please do your job without overdoing it.

Well, I think I’ll write about 3D printers that I couldn’t write last week.

So this time I thought I should write a systematic explanation of 3D printers,

If you search on the web, you will find many such things,

Since I myself have only used FDM 3D printers,

I would like to write mainly about experiences using 3D printers.

Alright,

Roughly speaking, I think there are about three methods of 3D printers currently on the market.

[Types of 3D printing]

First, stereolithography [SLA (Stereo Lithography Apparatus)]

This method uses a liquid resin that hardens with ultraviolet rays to create a shape.

The advantage is that the surface shape is beautiful.

The disadvantage is that it is difficult to exert strength. It is difficult to use outdoors because the influence of ultraviolet rays is strong.

However, there is also a method to increase strength by performing heat treatment after 3D printing.

You can also reduce the effects of UV rays by painting.

In fact, I have made a product using this method and sent it to a customer.

And the Fused Deposition Modeling method [FDM (Fused Deposition Modeling)]

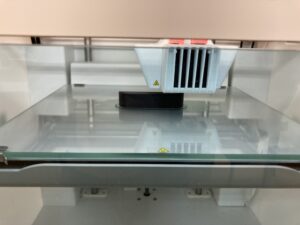

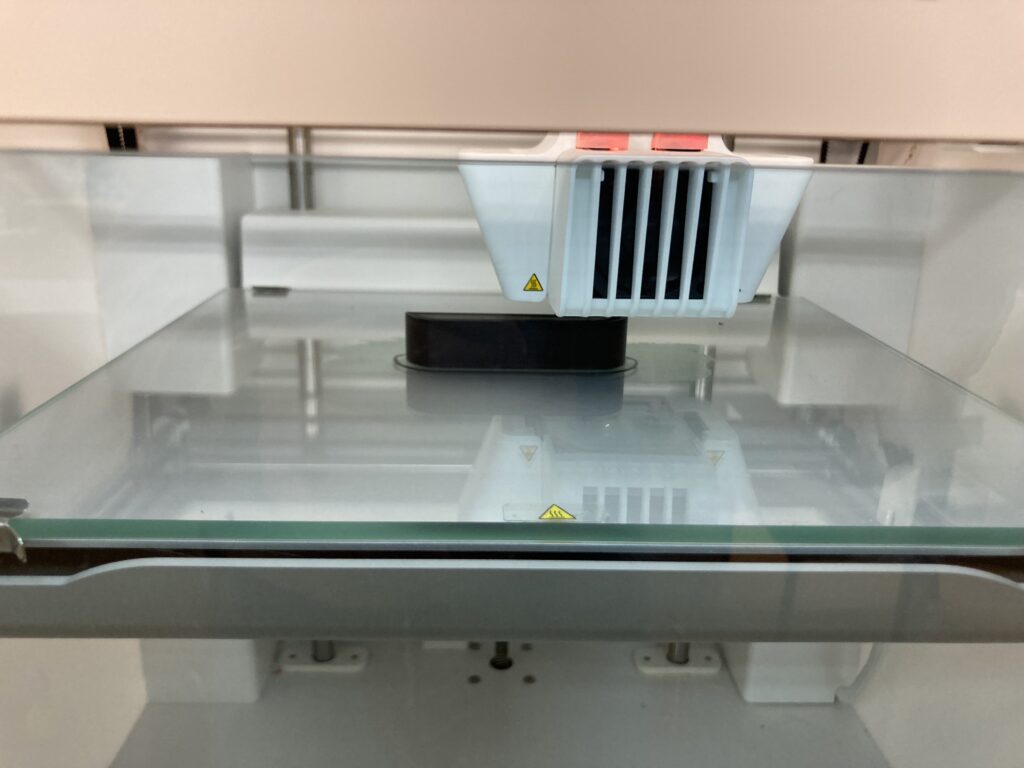

This is a 3D printer that Industry Lab also has.

Roughly speaking, imagine that the tip of a glue gun is very thin, and then draw the shape with one stroke from the bottom and print it.

The merit is that it is easier to handle than stereolithography because it does not use liquid. It is easier to produce strength than stereolithography.

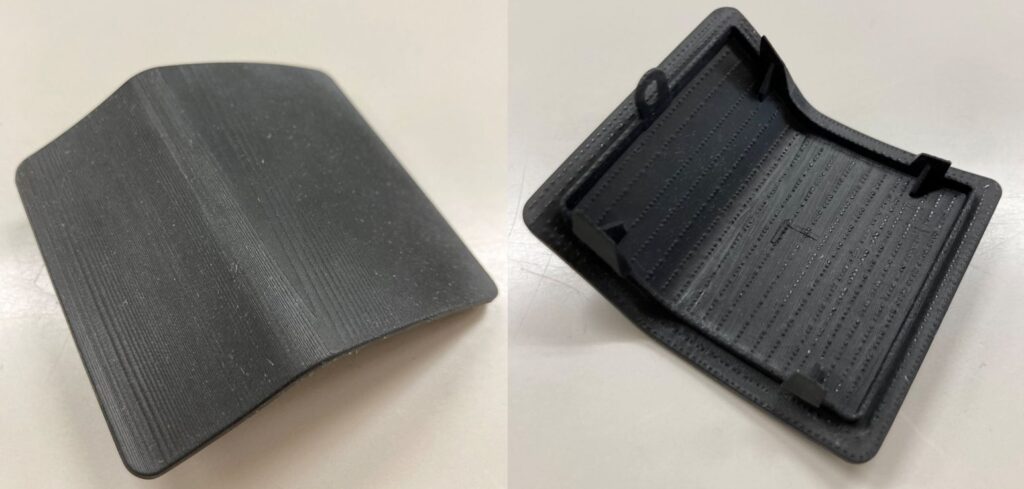

The demerit is that due to the manufacturing method, lateral streaks called lamination traces appear on the side.

I have also made products using this method and sent them to customers.

Also, the production method that I often see recently is the powder molding method [SLS (Selective Laser Sintering)].

Recently, I studied a manufacturing method in which powdered resin is melted and hardened with a laser.

This seems to be the main material of engineering plastics MC nylon at present, and is it an image that corresponds to such needs?

It seems that it was originally used for metal 3D printing technology.

There are other modeling methods, but I will omit them today.

In any method, the shape is built up in layers of about 0.05 to 0.3 mm, and it will be added more and more.

[Impressions of myself who have made products by 3D printing]

3D printing is still a manufacturing method that specializes in prototyping.

Write the reason.

・The cost is high because the production time is long due to the manufacturing method that builds up one layer at a time.

・Since it is a method of stacking layers one by one, it is difficult to achieve strength in the stacking direction.

・Because it is a method that builds up one layer at a time, it is often difficult to look at it compared to mass-produced products that use molds.

・There is almost no track record of conducting weather resistance tests for 3D printed products

・Large 3D printers are still rare, materials are limited, and prices are high.

That’s what it feels like.

By the way, 3D printers for home use are also sold cheaply, but they are not as beautiful as mass-produced products, and it is a bit difficult to use them as strong parts.

It depends on the application, but if you need a certain level of quality, I think it would be better to ask a vendor.

And there are still areas in the process of development.

But this industry is evolving really fast,

At an industrial machinery exhibition that I went to recently, there was a company that was developing a resin that could achieve the same level of strength and durability as the actual product using stereolithography.

In the early days, we received inquiries about plastic parts that were difficult to manufacture and had setbacks. So please do not hesitate to contact us.

I would like to do my best to meet your expectations as much as possible.

[Not only for individuals but also for businesses]

By the way, at present, 3D printed products containing carbon fiber seem to be as strong as aluminum, and I think it may be cheaper than cutting out aluminum. 3D printers specialize in complex shapes that cannot be handled by undercutting or by shaving.

In some cases, integration of parts can reduce costs.

Not only individuals but also traders will be interested in the manufacturing method in the future, so please contact us if you have any questions.

Last but not least, Industry Lab outsources manufacturing and production at the office that designs and verifies parts. Therefore, you can choose the place where you can do the best production and processing. In addition, we are good at proposing the optimal shape from the convenience of both usage and production. If you have any trouble with parts, please feel free to contact us.

Thank you for reading today.

Industry Love

インダストリーラブ

Industry Love

TEL:0533-56-7013

FAX:0533-56-7015

mail:otoiawase@industrylove.biz

address:〒442-0051 愛知県豊川市中央道3丁目31番地

address: 3-31 Chuo Expressway, Toyokawa City, Aichi Prefecture 442-0051

問合せ担当:中尾

Inquirer: Nakao